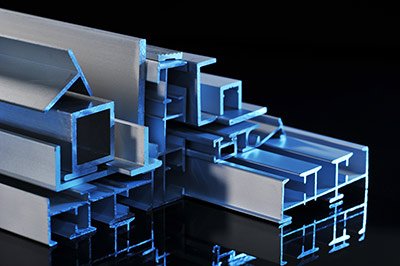

Your Partner in Precision Aluminium Extrusion

Are you looking for help in turning your design into reality? Then come to VIA INDIGOS for unmatched quality and detailed production facilities. We can extrude your aluminum into profiles of any design. The high-speed aluminum extrusion process gives us the opportunity to manufacture long lengths of aluminum parts with the same cross section. From appliance parts to transportation, from furniture to window frames, we’ve got you covered! In addition, the list doesn’t end here.

We have more to say about this. Guess what? You can add a touch of customization, finishes and coatings to everything that is produced with our custom aluminum extrusions. So, if you are in search of versatility, speed, and precision in your aluminum shapes, VIA INDIGOS’ aluminum extrusion capabilities are your perfect destination. Whether it’s aluminum extrusion profiles or extruded aluminum shapes, our expertise as aluminum extrusion suppliers ensures that your needs are met with precision and quality.

Your Aluminum Extrusion Experts, From Design to Delivery

With decades of experience, VIA INDIGOS simplifies even the most complex aluminum extrusion manufacturing requirements. From crafting intricate profiles to ensuring cost optimization amidst global tariffs, our network covers it all.

Untangle Your Manufacturing Needs with Local Expertise!

- Comprehensive Capabilities: With 12+ manufacturing processes, including aluminum extrusion, precision machining, and advanced surface treatments and finishing options we address complex production challenges across industries.

- Custom Manufacturing Solutions: From intricate aluminum profiles to tailored finishing options, we ensure every component is designed to meet your specific requirements with the best quality alloy creation.

- Tailored Scalability: Whether for small batches or high-volume production, our localized manufacturing expertise ensures timely delivery with precision craftsmanship.

- Reliable Precision: Each product adheres to industry certifications, guaranteeing durability, dimensional accuracy, and exceptional performance.

- Cost Optimization Amidst Tariffs: Manufacturing in India enables us to overcome high tariff barriers, offering globally competitive pricing and supply chain reliability without compromising standards.

Post Process

From Raw Material to Finished Product:

Our Strength!

Whether you require robust 6061 aluminium for structural strength or intricate profiles for electronics, as an complex aluminum extrusion suppliers, we’ve got you covered.

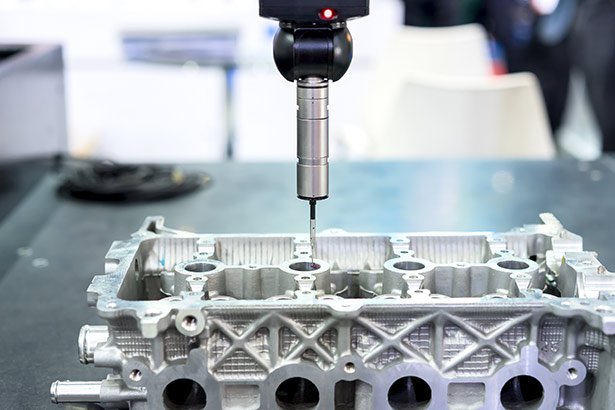

Our capabilities extend from material selection to secondary operations like anodizing, powder coating, and CNC machining, ensuring a seamless journey from raw material to finished product. At VIA INDIGOS, we combine advanced technologieswith industry expertise to ensure exceptional performance and reliabilityin every component.

From Design to Delivery - Extrude with us

At VIA INDIGOS, we don’t just extrude aluminium; we craft solutions tailored to your unique needs. From designing custom profiles to applying advanced finishes, our services deliver precision at every step. With expertise in reverse engineering, robust logistics, and a skilled team ensuring door-to-door delivery, we take your projects from concept to completion with unmatched efficiency and reliability.

Got Questions? We’ve Got Answers

Q1. How do you ensure precision in custom aluminum extrusion profiles?

Answer: Our advanced extrusion technology and CNC machining ensure intricate cross-sections and precise dimensions, meeting tight tolerances for complex designs.

Q2. What is your lead time for manufacturing custom extrusion dies?

Answer: Typically, our custom extrusion dies are ready within 2 weeks. Once approved, we proceed with production to ensure timely delivery.

Q3. How do you handle large-scale aluminum extrusion projects while maintaining quality?

Answer: With our streamlined production workflows with our dedicated aluminium extrusion partners and adherence to international quality standards, we efficiently manage high-volume orders without compromising precision or durability.

Q4. What secondary operations do you offer for extruded aluminum parts?

Answer: We provide comprehensive secondary operations, including precision cutting, bending stamping, welding, CNC machining, anodizing, CED & Powder Coating and surface treatments tailored to your application needs.

Q5. Can you assist with reverse engineering for legacy aluminum extrusion designs?

Answer: Absolutely. Our reverse engineering capabilities allow us to deconstruct and optimize outdated designs, ensuring compatibility and improved performance.

Q6. Which aluminum alloys do you specialize in for extrusion projects?

Answer: We work with a wide range of aluminium alloys, including 6005-T5, 6101-T61, and 7075-T6, to match your project’s mechanical and structural requirements. We can also cater 5000 SERIES for specially curated projects.

Q7. How do you achieve slim wall thickness while ensuring immense strength in extruded aluminum profiles?

Answer: By combining high-strength alloys with precision extrusion techniques, we manufacture lightweight profiles with slim walls that maintain exceptional structural integrity, ideal for demanding applications.

Q8. How do you address thermal expansion in aluminum extrusion processes?

Answer: Through precise material selection and thermal stress simulation, we minimize expansion-related issues, ensuring consistent performance even under extreme conditions.

Q9. What certifications and standards do your extruded products comply with?

Answer: All our aluminum extrusion processes adhere to stringent industry certifications, including BIS and ISO standards, ensuring compliance across automotive, construction, and consumer product sectors.

Q10. How do you support clients with large or complex aluminum extrusion requirements?

Answer: We draw from a vast network of manufacturing partners, selecting the most suitable ones based on project requirements such as size, quantity, and specific needs. Our dedicated on-ground team ensures seamless coordination, strict quality assurance, and timely delivery for projects of any scale or complexity. You can trust us one of the most reliable complex aluminum extrusion manufacturer.

PRODUCTS MANUFACTURED THROUGH aluminium extrusion

Tubes

Brackets

Channels

Supports