From Factory to Front Door: How Your Products Travel the World

- VIA INDIGOS

When you order a product online, the journey it takes to reach your hands is nothing short of remarkable. Behind the convenience of e-commerce lies a complex, coordinated effort that spans continents, processes, and technologies. Let’s break down the lifecycle of a product, from its conception at a factory to its final delivery at your doorstep, and explore the key milestones along the way.

1. The Idea Becomes a Blueprint: RFQ and Feasibility Analysis

Every product starts with a concept. A company or customer sends a Request for Quotation (RFQ) to potential manufacturers. This document outlines the product’s specifications, expected volume, materials, and other requirements. The global RFQ market is valued at over $18 billion, reflecting the growing trend of outsourcing manufacturing.

Before committing to production, manufacturers conduct a feasibility analysis to ensure they can meet the technical, financial, and logistical demands. This step involves assessing:

• Material sourcing: Can raw materials be procured cost-effectively? For example, sourcing aluminum or other materials might depend on global suppliers, which can lead to pricing volatility.

• Production capacity: Do the facilities have the necessary machines and workforce to fulfill the order on time? Many manufacturers operate at near capacity during peak seasons, creating tight schedules.

• Regulatory compliance: Does the product meet the required legal and safety standards for its target markets? Products exported internationally often need certifications like CE, RoHS, or FDA approval.

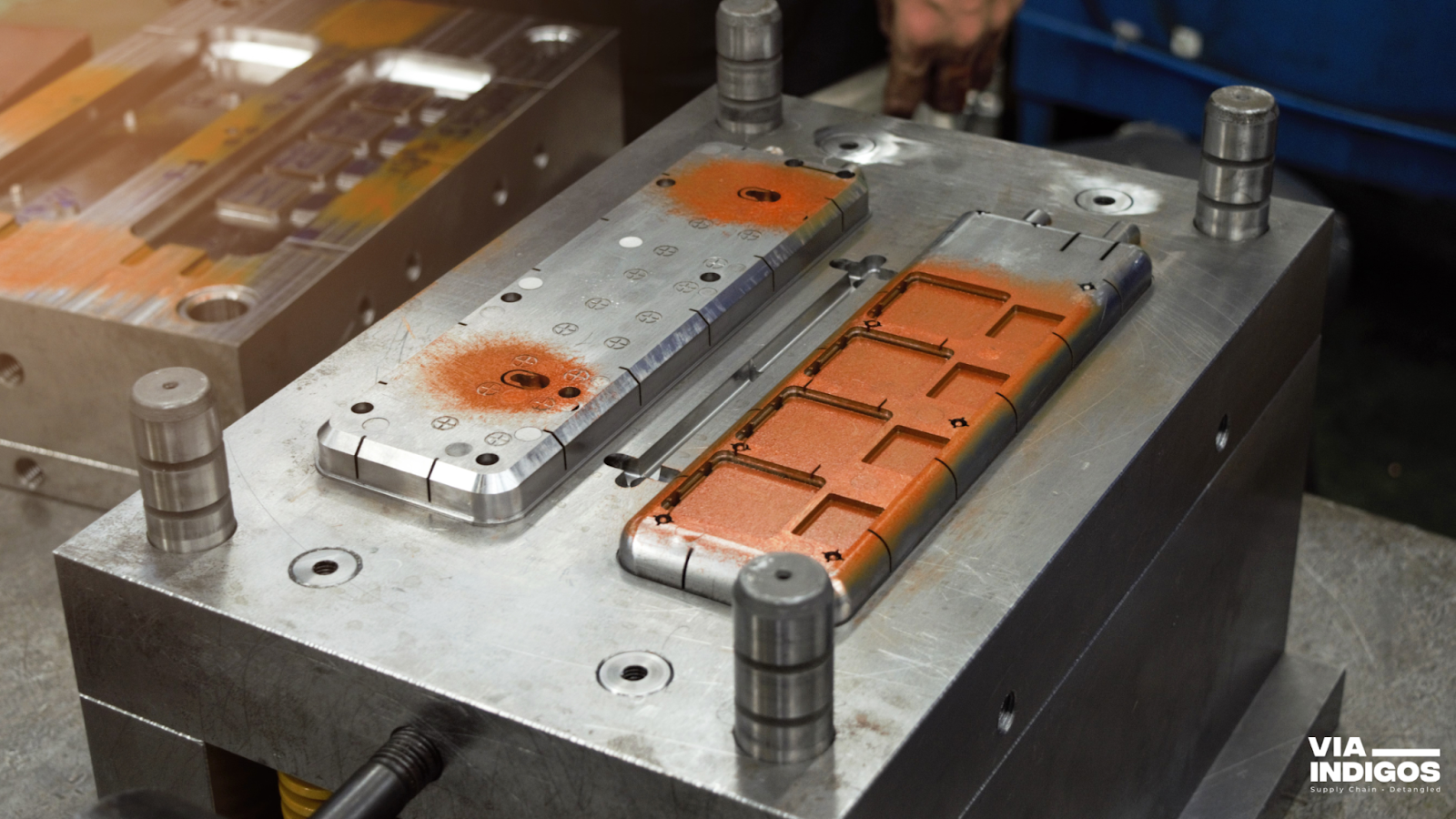

Precision manufacturing: Advanced 3D design for efficient production.

2. Quotation and Tooling

Once feasibility is confirmed, the manufacturer provides a detailed quotation outlining costs for materials, labor, and tooling. Tooling involves creating specialized molds, dies, or equipment to produce the product efficiently and consistently.

For example:

- Injection molds for plastic components often cost between $10,000 to $50,000 depending on complexity.

- Automotive tooling for large-scale production can run into the hundreds of thousands of dollars.

Tooling takes an average of 4- 12 weeks and represents a critical step in ensuring mass production can begin smoothly.

Cost-efficient tooling solutions: From injection molds to automotive dies, ensuring seamless production with precision and speed.

3. First Article Inspection Report (FAIR)

Before mass production, a prototype or First Article is created and inspected for compliance with design specifications. This stage is vital to catching issues early, saving time and money.

• Dimensional checks: Do all physical dimensions align with the blueprint? This is crucial for assembly and compatibility with other parts.

• Material testing: Are the materials durable and compliant with safety standards? For example, medical-grade plastics undergo rigorous stress tests.

• Functional testing: Does the product work as intended? Over 60% of functional defects are identified and corrected at this stage.

Once testing is complete, results are compiled into a First Article Inspection Report (FAIR). This document provides a roadmap for scaling production while ensuring quality remains consistent.

A quality engineer meticulously conducts a First Article Inspection, bridging design intent with flawless execution.

4. Production: Scaling Up

With the FAIR approved, the manufacturer begins full-scale production. This involves:

• Material procurement: Manufacturers rely on supply chains to deliver raw materials in a just-in-time system to avoid excessive inventory costs.

• Batch production: Products are often produced in batches to optimize efficiency and manage quality control.

• Process monitoring: Advanced technologies like IoT sensors track machine performance, reducing downtime by up to 20% in modern factories.

For context:

- Small electronic devices might be produced in 2-4 weeks.

- Complex machinery can take 8-12 weeks depending on order volume and specifications.

Optimizing batch production with precision manufacturing, IoT-driven process monitoring, and just-in-time material procurement for seamless scalability.

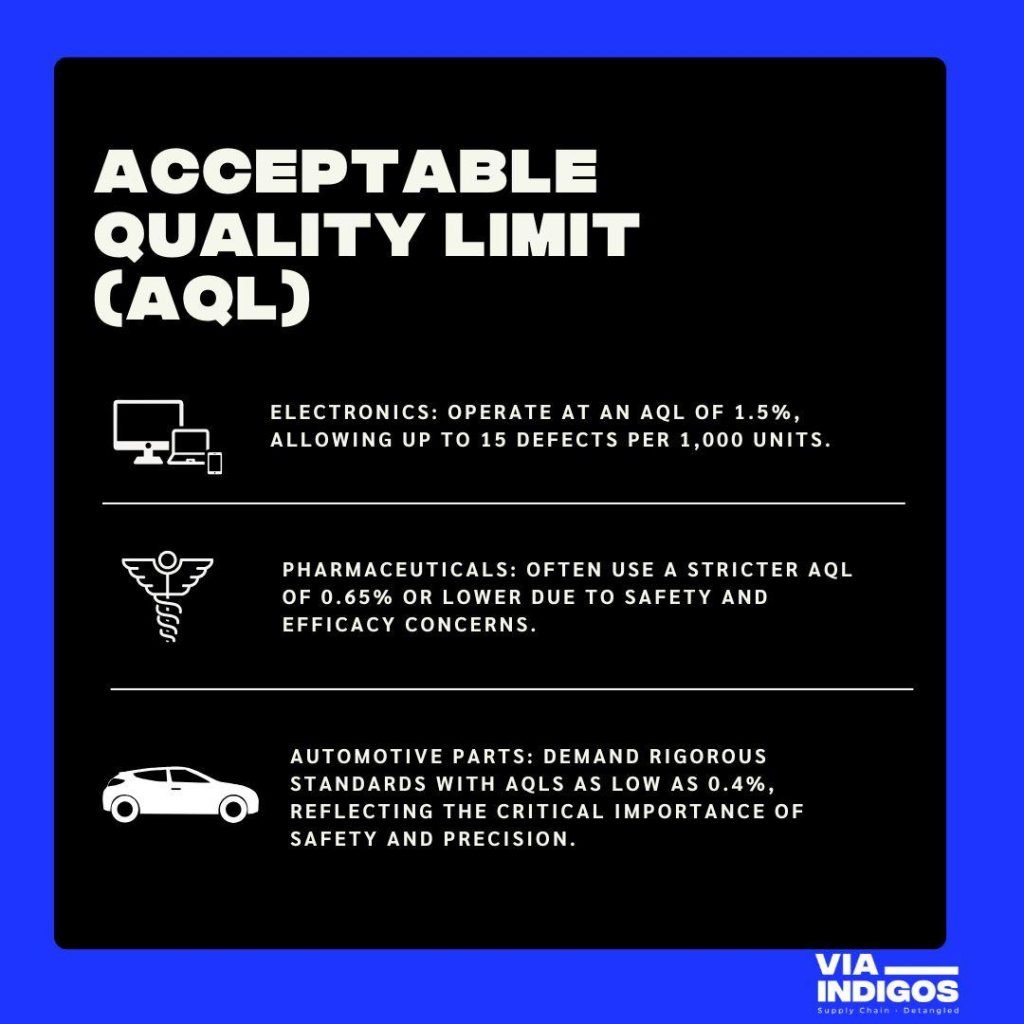

5. Quality Inspections: Gatekeepers of Excellence

Ensuring quality at scale is a challenge. Manufacturers implement rigorous inspection protocols, including:

• Inline inspections: Catching defects during production, rather than at the end, reduces waste and rework costs.

• Final inspections: These assess functionality, appearance, and packaging, ensuring the product meets both client and consumer expectations.

• AQL standards: Many industries use the Acceptable Quality Limit (AQL) system to define acceptable defect rates. For example, consumer electronics often operate at an AQL of 1.5%.

6. Packaging and Logistics

After passing inspections, products are prepared for shipment. Packaging must balance protection with efficiency to minimize costs.

• Protective measures: Items might be wrapped in bubble wrap, placed in foam inserts, or secured with cardboard dividers.

• Space optimization: Packing items strategically can reduce freight costs by as much as 15-20%.

Products then embark on their journey through one or more modes of transportation:

• Sea freight: Ideal for large shipments, it accounts for 90% of global trade volume but requires longer lead times.

• Air freight: Used for high-value, low-weight goods, air transport is faster but can cost up to 10x more than sea freight.

• Road freight: Often handles domestic transport and final delivery legs.

Products inspected and staged for final packaging: Balancing quality assurance and efficiency before shipment preparation.

7. Warehousing and Distribution

Upon arrival in the destination country, products are stored in warehouses. These facilities sort, manage, and distribute goods to their final destinations.

Modern warehouses employ technologies like:

• Robotics: Automated systems handle tasks like picking and packing, improving efficiency by 30-40%.

• Warehouse Management Systems (WMS): Software tracks inventory, reducing errors and improving fulfillment times.

Warehousing also serves as a buffer, ensuring businesses can meet fluctuating consumer demand.

Efficient Warehousing and Distribution Solutions: Streamline Inventory Management, Optimize Logistics, and Ensure On-Time Delivery.

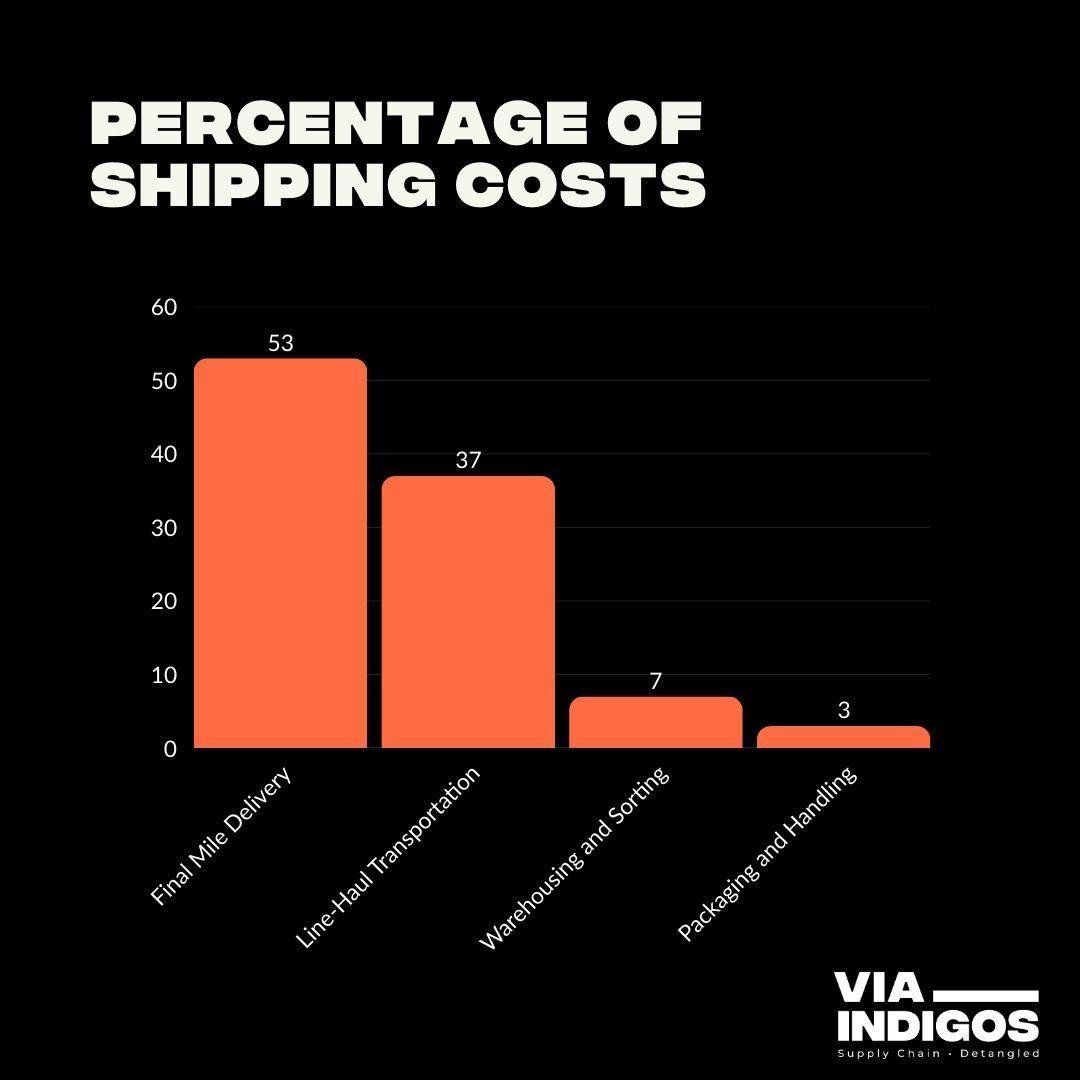

8. The Final Mile: Delivery to Your Doorstep

The final mile is often the most challenging and expensive part of the journey. It involves transporting products from local warehouses to individual customers.

Key challenges include:

• Route optimization: AI-driven systems minimize delivery times while reducing costs.

• Meeting consumer expectations: With more than 80% of shoppers expecting next-day delivery, speed and reliability are critical.

• Innovative solutions: Companies are experimenting with drone deliveries and autonomous vehicles to improve efficiency.

Interestingly, final mile delivery accounts for 53% of total shipping costs, making it a focal point for cost-saving innovations.

The Bigger Picture: Supply Chain Synchronization

Behind every delivered product lies an intricate dance of planning, technology, and logistics. From RFQs to final mile delivery, every step must align to ensure products are delivered efficiently and cost-effectively.

• Global Supply Chain Stats:

- The average product travels over 15,000 kilometers from factory to consumer.

- Supply chain disruptions cost businesses an estimated $184 billion annually.

- Advanced logistics technologies have improved efficiency by 30% for companies that adopt them.

“With a strong presence in India and an extensive network of expert manufacturers, we help you reduce tariffs, cut lead times, and navigate supply chain challenges.

The next time you unbox a package, consider the remarkable journey it took to reach you. From blueprint to delivery, the process involves countless professionals, sophisticated technologies, and global coordination. It’s a testament to the complexity and ingenuity of modern supply chains.

Modern supply chains: From blueprints to your doorstep, a global journey powered by innovation and seamless coordination

Why VIA INDIGOS for Global Supply Chain Solutions?

At VIA INDIGOS, we simplify the complexity of global supply chains by managing every detail from factory to front door. With a strong presence in India and a trusted network of production partners, we handle manufacturing, inspection, and logistics to ensure your products reach their destination on time and within budget.

We combine India’s manufacturing advantages with strategic supply chain expertise, helping you navigate challenges like tariffs, lead times, and cross-border complexities. Our goal is to optimize every stage of the process, offering you peace of mind and seamless delivery.

What Sets VIA INDIGOS Apart?

• Global Reach, Local Expertise: We connect you to India’s manufacturing powerhouses while ensuring smooth international logistics.

• Integrated Supply Chain Management: From manufacturing to packaging and shipping, we oversee every step of the journey.

• Tariff, Cost and Time Efficiency: Reduce tariffs, cut lead times, and avoid delays with our tailored solutions.

• Reliable Delivery: Our logistics expertise ensures your products arrive as planned, no matter where they’re headed.

• Transparent Communication: Stay informed with regular updates and complete visibility into your supply chain.

At VIA INDIGOS, we are more than a Supply Chain and manufacturing partner—with boots on the ground in India, we’re your trusted ally, ensuring your products are manufactured with the best quality and cost-effectively.