BLOW MOULDING Manufacturer

- 35+ blow moulding facilites ensuring unmatched capacity.

- Handles PET, HDPE, ABS, PP, and a variety of other materials.

- Sizes ranging from 10ml bottles to 3000L tanks.

- Precision-engineered for faster production cycles and consistent quality

From Vision to Volume - Speed and Precision with VIA INDIGOS

Precision, durability, and innovation converge in VIA INDIGOS’ blow moulding expertise. From high-capacity containers to components for children’s rides, road construction stands, and beyond, we deliver tailored solutions to meet diverse industry needs. Whether crafting intricate designs or manufacturing high-strength products, we focus on delivering exceptional quality and efficiency while ensuring faster production cycles to meet your tight deadlines.

LET'S BLOW AND SHAPE THE FUTURE TOGETHER !

From small toys to industrial tanks, tailored for your custom requirements with unmatched speed and efficiency.

Why VIA INDIGOS?

- Versatility in Design: From fuel tanks to spray bottles, we excel at manufacturing components with complex geometries and thin wall sections for enhanced efficiency.

- High-Volume Reliability: Our vetted facilities are equipped to handle high-capacity production with consistency in every batch.

- Material Mastery: Whether HDPE, PET, or Polypropylene, we ensure the right materials are chosen for durability, flexibility, and environmental resistance.

- End-to-End Solutions: Beyond moulding, we offer surface finishing, assembly, and logistics support, simplifying your supply chain.

- Competitive Edge: Manufacturing in India allows us to overcome tariff barriers and offer globally competitive pricing for your blow moulded products.

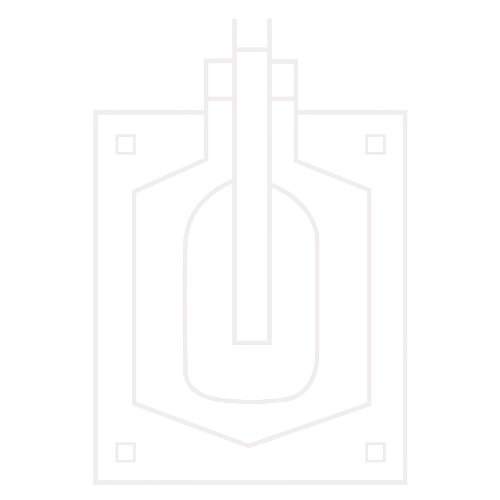

Blow moulding isn’t just a manufacturing process – it’s a precise technique that transforms raw material into seamless, high-strength hollow products. Here’s a look at how injection blow moulding works, why it’s unique for creating consistent wall thickness and flawless structural integrity, and how our expertise ensures the best results for your needs.

BUT HOW DOES INJECTION BLOW MOULDING ACTUALLY WORK?

Firstly, a small, test-tube-shaped piece of plastic goes through the process of injection moulding to turn it into a preform. Which is then heated and shifted to a blow moulding station. Following this, in the next step using pressurised air, that preform is inflated into the desired shape. Hence, as a result a seamless, hollow product with consistent wall thickness and excellent structural integrity is produced.

This is not it. Injection blow moulding has a lot more to know. In the large family of blow moulding, Injection blow moulding is part of the many techniques. And its subtypes are much more to look into. As each one of them is suited for a different application and product requirement. Come let’s blow your minds:

For producing hollow parts by extruding molten plastic into a tubular shape (parison) this type of process is ideal. This process inflates the molten plastic inside a mould to give it the form of a final product. It’s usually used to produce items like bottles, containers, and automotive parts. The process is highly versatile. It is capable of accommodating a wide range of shapes and sizes, making it a go-to method for large-scale production.

To leverage the need of small to medium sized products this type of injection moulding is the best pick. It is high speed and it ensures continuous flow of materials too! Opting for this process also results in efficient and cost-effective manufacturing. In the production of packaging items like detergent bottles and small containers, this type of blow moulding process is taken into measure. The consistency in quality and lesser material wastage is observed in this process because of this nature of being continuous.

For products that are large, hollow and often circular in shape like barrels and water tanks, this blow moulding technique is usually opted. In this process the concept of rotating wheel allows manufacturing units for the simultaneous production of multiple items, hence increasing efficiency. For the manufacturing of products that require uniform wall thickness and high structural integrity, especially in larger dimensions it is a preferred method.

For producing small to medium-sized containers with intricate designs and consistent wall thickness, this method offers unparalleled precision, making it the most ideal choice. Pharmaceutical and cosmetic industries for bottles and jars, this process turns out to be a perfect choice. The process ensures that each product is lightweight and durable, with smooth surfaces and detailed features.

Intermittent the word says it all. Here, in this process it involves pausing the extrusion process. It is done to allow the creation of intricate details and complex geometry to form. Such type of moulding is often used for specialty items that are in need of detailed features or different wall thicknesses. For manufacturing custom made products this process offers flexibility of design and quantity.

Got Questions? We’ve Got Answers

Q1. How do you achieve uniform wall thickness in blow-moulded products with complex geometries?

Answer: Our advanced blow moulding techniques, including precision control of airflow and mold design, ensure consistent wall thickness even in intricate shapes, meeting high-performance requirements across industries like automotive, consumer goods, and toys.

Q2. What is the largest size product you can manufacture using blow moulding?

Answer: We can produce blow-moulded items ranging from 10 ml containers to large 3000-liter tanks, catering to diverse needs in industrial, agricultural, and household applications.

Q3. Which industries benefit the most from your blow moulding capabilities?

Answer: Our solutions cater to industries such as automotive (air ducts, fuel tanks), consumer products (bottles, containers), toys (durable plastic toys), and industrial applications (barrels, sprayer tanks).

Q4. What materials are best suited for blow moulding durable and lightweight products?

Answer: Materials like HDPE, PET, and Polypropylene are commonly used, offering strength, flexibility, and chemical resistance. We guide material selection based on your specific application needs.

Q5. How do you manage high-volume production without sacrificing quality?

Answer: Leveraging our state-of-the-art facilities and optimized production workflows with our dedicated manufacturing partners, we maintain consistency and precision across large-scale production runs, ensuring every piece meets stringent quality standards.

Q6. What advanced blow moulding techniques do you offer for unique product requirements?

Answer: We specialize in extrusion blow moulding for large hollow parts, injection blow moulding for precision components, and stretch blow moulding for enhanced strength and clarity in products like bottles.

Q7. Can you assist with reverse engineering or tooling improvements for blow-moulded products?

Answer: Absolutely. Our team specializes in reverse engineering and tooling lifecycle management, optimizing legacy designs for modern blow moulding techniques and enhanced production efficiency. With trusted tooling partners, we achieve exceptional lead times, offering the precision and responsiveness of an in-house tooling operation.

Q8. How do you ensure compliance with international quality standards?

Answer: Our blow moulding processes adhere to rigorous standards, ensuring consistency, durability, and safety for applications in regulated industries like automotive and industrial equipment. We are partnered with the most efficient and advance blow moulding experts.

Q9. What are your capabilities for multi-material blow moulding?

Answer: We offer solutions for co-extrusion blow moulding, enabling multi-layered products with properties like enhanced strength, thermal insulation, and chemical resistance.

Q10. How do you address sustainability in blow moulding production?

Answer: We optimize material usage, employ recyclable plastics where possible, and implement energy-efficient manufacturing practices to reduce waste and minimize environmental impact.

DISCUSS YOUR REQUIREMENT!

TWO-STAGE INJECTION STRETCH BLOW MOULDING

SINGLE STAGE MACHINE

In this process, the single stage signifies that the preform and the final product are made within the same machine. This technique helps in streamlining production and reducing handling time. Hence, it turns out to be a highly efficient process. It is an ideal pick for producing high-quality bottles with excellent clarity and strength, commonly used in the beverage industry. To produce products of light weight and supreme quality, this technique is the best choice.

DOUBLE STAGE MACHINE

Process Stage 1st

Double stage means the preform is created in one stage and the final product in another.

Process Stage 2nd

It is then reheated and moulded into the final product in the second stage. This process offers greater control over the material to be moulded and the final shape as well. Therefore, this process is ideal for making complex designs and higher production volumes. Particularly for beverages and personal care products, where there is demand for high quality bottles in larger batches, this process is preferred.

MATERIALS USED IN INJECTION BLOW MOULDING

– Polyethylene (PE):

High-density Polyethylene (HDPE): This material holds the property of being strong and impact-resistant, hence making it ideal for fuel tanks, air ducts, sprayer tanks, conduit, and bottles.

Low-density Polyethylene (LDPE): It is flexible and lightweight in nature, hence suitable for toys, household containers, sporting goods, and IV bags.

– Polyethylene Terephthalate (PET): It holds the property of strength and is clear in nature, so it is perfect for manufacturing water bottles, medical bottles, jars, and specimen containers.

– Polypropylene (PP): Resistant to chemicals and heat, used for toys, lab equipment, feed troughs, and custom packaging.

– Polyvinyl Chloride (PVC): Durable and versatile, often used for air intake manifolds, canisters, and industrial containers.

– Nylon or Polyamide (PA):

Tough and wear-resistant in nature, hence commonly used in producing engine components and bumper components.

– Polycarbonate (PC): Has the capability to high impact resistance and clarity, ideal for medical bottles and lab equipment.

– Copolyester: It offers clarity and chemical resistance in its characteristics, so it is used in pharmaceutical containers and water bottles.

– Cyclic Olefin Copolymer (COC): High transparency and dimensional stability, used in test tubes and specimen containers.

– Acrylonitrile Butadiene Styrene (ABS): Strong and lightweight, used in furniture components like chair bases and table legs.

MATERIALS CHECKED! NOW, GET YOURSELVES BLOWN WITH VIA INDIGOS SERVICES!

At VIA INDIGOS, we provide you with a comprehensive suite of services, which keeps us committed to providing an excellent quality customer experience for you. After our first hello, you will be driven through our entire process, from reverse engineering to quality inspection to vendor approval. Additionally, you will get managed inventory, just-in-time delivery, and tool management too. Because, as you are aware, our major motive always remains to streamline your business with the ultimate level of operational efficiency.

Join hands with us to avail services made just for you! A few of our services are:

PRODUCTS MANUFACTURED THROUGH BLOW MOULDING

Fuel Tank

Spray Bottles

Plastic Barrels

Air Ducts

PRODUCTS MANUFACTURED THROUGH BLOW MOULDING

LET'S BLOW AND SHAPE THE FUTURE TOGETHER !

From small toys to giant tanks, we mould your vision into reality. Big ideas can’t wait, reach out now! Let’s create something extraordinary!