CNC MACHINING

1,000+ Machines | 250+ Milling Centers | Precision to 3 Microns

- Handling diameters up to 2,500 mm.

- Equipped for heavy-duty and large-scale machining.

- Ultra-precision for intricate parts with fast turnaround times.

Precision, Speed, and Scale - Perfected at VIA INDIGOS

With a robust infrastructure network of 1,000+ cutting-edge machines and state-of-the-art facilities, we combine precision engineering with unparalleled scalability to deliver top-tier components, no matter how complex the requirements.

From crafting intricate parts for precision-critical applications to handling heavy-duty machining for large-scale projects, our expertise spans across the spectrum. Our operations are powered by a commitment to speed, ensuring fast turnaround times without compromising on accuracy or quality. Whether it’s high-volume production, prototypes, or specialized one-off designs, VIA INDIGOS is equipped to deliver excellence at every stage of your production journey.

LET’S GET YOUR PARTS MACHINED!

From tight tolerances to rapid turnarounds, VIA INDIGOS delivers precision machined components you can rely on.

Why Trust VIA INDIGOS for CNC Machining?

- Precision at Every Turn: With tolerances as tight as ±0.03 mm, our CNC and VMC machining delivers components that meet the most exacting standards.

- Unmatched Capabilities: From 4-axis and 5-axis milling to deep-hole drilling and heavy-duty machining for large diameters, we handle projects of any complexity and scale.

- Material Expertise You Can Rely On: Specializing in machining aluminum, titanium, stainless steel, and other high-performance metals, we ensure optimal performance and durability.

- Integrated Solutions: From machining to post-processing like passivation, heat treatment, and electroplating, we provide end-to-end support for your project.

- Cost-Effective Manufacturing: Leveraging our India-based facilities, we overcome tariff barriers while ensuring globally competitive pricing and timely delivery.

Got Questions? We’ve Got Answers

Q1. What materials can you machine using CNC and VMC processes?

Answer: Our capabilities span a wide range of materials, including stainless steel, titanium, nickel alloys, copper alloys, industrial plastics like PEEK and ULTEM, and exotic metals like Inconel, Tantalum, and Zirconium.

Q2. How do you achieve ultra-precision machining with tight tolerances?

Answer: We utilize state-of-the-art CNC and VMC equipment capable of achieving tolerances as tight as ±0.03 mm, ensuring accuracy for intricate components in industries like automotive and consumer electronics.

Q3. What post-processing services do you offer for machined components?

Answer: Our comprehensive post-processing options include heat treatment, electroplating, passivation, anodizing, peening, CED & powder coating, black oxiding and case hardening, and abrasive blasting, ensuring enhanced durability and surface quality.

Q4. How do you handle large diameters or long shafts in machining?

Answer: Our facilities are equipped with vertical turning lathes (up to 2,500 mm), radial drilling machines (up to 3,000 mm), and long-shaft machining capabilities (up to 1,500 mm), enabling us to handle large and complex components.

Q5. What industries benefit the most from your CNC and VMC machining capabilities?

Answer: Our expertise supports diverse industries, including automotive (engine parts, housings), construction (structural components), consumer goods (appliance parts), electronics (precision housings), and industrial equipment.

Q6. Can you assist with reverse engineering for legacy components?

Answer: Absolutely. Our VIRE (VIA INDIGOS Reverse Engineering) services enable us to analyze and reconstruct machining processes, optimize legacy designs, and provide complete documentation for seamless integration.

Q7. How do you ensure consistency and quality in high-volume production?

Answer: Our strict adherence to ISO and ASTM standards, combined with advanced monitoring systems, guarantees precision and consistency across large-scale production runs. We implement advanced quality techniques such as PPAP, FMEA, FAIR, Six Sigma, APQP (Advanced Product Quality Planning), MSA (Measurement System Analysis), SPC (Statistical Process Control), etc. to ensure the highest standards of manufacturing excellence.

Q8. Do you offer machining for complex geometries like 5-axis operations?

Answer: Yes, our advanced 5-axis milling and mill-turn machines are equipped to handle intricate geometries, delivering highly accurate and complex components with reduced lead times.

Q9. What measures do you take to maximize tool life and operational efficiency?

Answer: Our VITLM (VIA INDIGOS Tool Life Management) system tracks tool wear, schedules maintenance, and optimizes tool performance, minimizing downtime and ensuring consistent quality. We have a dedicated team to ensure deliver consistency.

Q10. How do you support supply chain efficiency for CNC and VMC projects?

Answer: We leverage our extensive network of manufacturing partners over 1300 HMC & VMC. Our on-ground team to ensure streamlined operations, timely deliveries, and real-time tracking for seamless supply chain management.

Processes That Shape Precision. One Cut at a Time!

Explore Our HMC/VMC Capabilities

Machine Shop Capabilities

Our fleet of cutting-edge machines enables us to handle everything from micro-level precision to heavy-duty industrial needs.

- 5-AXIS MILLING AND 5-AXIS MILL-TURN MACHINES

- 1,000+ CNC TURNING MACHINES

- MACHINING OF LARGE DIAMETERS UP TO 1000 MM

- ULTRA PRECISION MACHINING UP TO 3 MICRONS

- 250+ CNC MILLING MACHINS

- CNC GUN DRILLING MACHINE,1000 MM DEEP, 5-35 MM DIAMETER

- MACHINING OF LONG SHAFTS UP TO 1500 MM

- ULTRA PRECISION MACHINING UP TO 3 MICRONS

- HEAVY DUTY MACHINERY

- VERTICAL TURNING LATHE (VTL) – 2,500 MM

- RADIAL DRILLING MACHINE (RDM) – 3,000 MM

- HORIZONTAL BORING MACHINE (HBM)- 125MM

Tight Tolerance, Guaranteed Precision!

Our state-of-the-art equipment ensures your parts meet the tightest tolerances, no matter the application.

| Metals,PEEK,And ULTEM with Drawing | Other Plastics with Drawing | No Drawing | |

|---|---|---|---|

| Linear Dimension |

+/- 0.01 mm +/- 0.0003 inch |

+/- 0.05 mm +/- 0.002 inch |

ISO 2768 Medium |

| Hole Diameters(Not Reamed) |

+/- 0.008 mm +/- 0.0003 inch |

+/- 0.05 mm +/- 0.002 inch |

ISO 2768 Medium |

| Shaft Diameters |

+/- 0.004 degree +/- 0.00016 inch |

+/- 0.05 mm +/- 0.002 inch |

ISO 2768 Medium |

Finishing Strong: Post-Processing Expertise

Beyond precision machining, VIA INDIGOS ensures your parts meet exacting standards with world-class post-processing /secondary operations. Every part is refined to perfection to deliver on your specific needs-be it performance, durability, or flawless finishes.

Services

Surface Finishing: Anodizing, Powder Coating, Abrasive Blasting, Passivation

Heat Treatment: Carburizing, Stress Relieving, Case Hardening Assembly & Integration: Streamlining complex projects

Special Processes: Chem Coating, Electroplating, and more

Materials That Deliver Strength and Performance

Our CNC capabilities span a diverse range of materials, ensuring strength, durability, and precision for every industry we serve. Whether metals or specialized industrial plastics, VIA INDIGOS delivers components tailored to your specifications.

Materials Handled:

Titanium, Nickel Alloys, Copper, Monel, Stainless Steel, Inconel, Tantalum, Duplex SS, Exotic Metal Cladded Materials

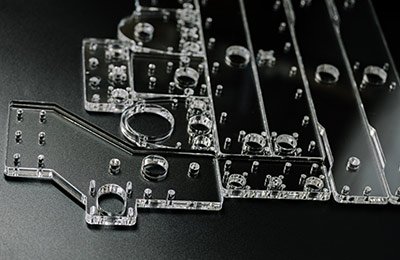

Industrial Plastics: Acrylic, Delrin, Nylon, Polycarbonate, PTFE

Not sure if your material is on the list? Reach out-we’ll definitely make it work.

Precision Delivered! Now, Explore VIA INDIGOS Services for Complete Machining Solutions!

Our services go beyond machining to ensure your operational efficiency. From just-in-time inventory management to reverse engineering, VIA INDIGOS delivers precision and reliability at every step. Explore tailored solutions designed to meet your unique challenges with unmatched quality and support.

Products Manufactured through CNC/VMC

Pistons

Shafts

Flanges

Housings

Products Manufactured through CNC/VMC

LET’S GET YOUR PARTS MACHINED!

From tight tolerances to rapid turnarounds, VIA INDIGOS delivers precision machined components you can rely on.