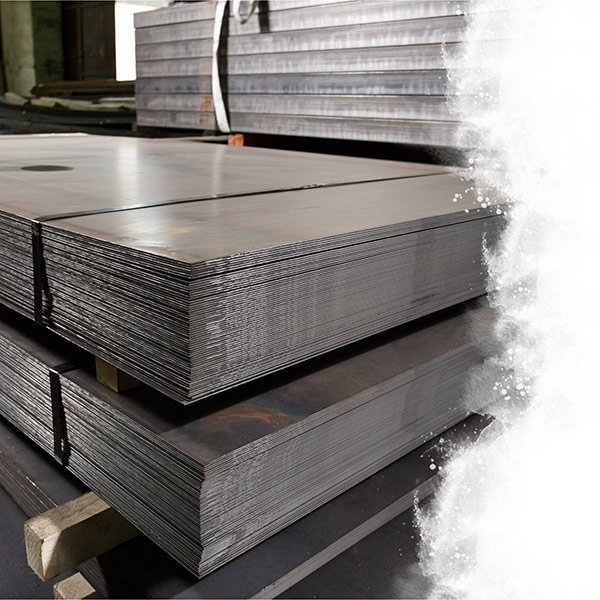

SHEET METAL FABRICATION

- 27+ Cutting, bending and welding Facilities

- Certified to ASME SEC IX, ISO 15610

- Tolerances Up to 5 Microns

- Inhouse Painting & Coating Services

- Pneumatic & Hydrostatic Pressure Testing

Fabrication That Delivers Speed, Scale, and Precision

At VIA INDIGOS, we combine expertise and advanced technology to set new standards in metal fabrication. With network of 27+ facilities and global certifications, we cater to projects of every scale, ensuring timely delivery without compromising on quality.

Our services cover Laser cutting, bending, welding and grinding, tailored to meet your exact specifications. Whether it’s customized small batches or high-volume industrial production, our certified welders and engineers deliver results that last.

To further streamline your operations, we offer in-house pressure testing, painting, and coating, making VIA INDIGOS your all-in-one partner for fabrication needs. From concept to completion, we ensure every part meets the highest industry benchmarks for reliability and performance.

BEND IT. CUT IT. SHAPE IT - WITH VIA INDIGOS!

Tailored Fabrication for Every Scale – From Small Batches to Large-Volume Manufacturing

Fabrication Processes That Shape Excellence

Your Fabrication Partner: Excellence Delivered at Every Stage

- Cutting-Edge Facilities: Equipped with the latest technology, including bending, laser cutting, and welding, for flawless fabrication results.

- Tailored Manufacturing Solutions: Designed to meet the unique demands of your project, whether small-scale runs or large industrial volumes.

- End-to-End Project Management: From raw material sourcing to quality inspections and final delivery, we handle every step seamlessly.

- Global Certifications: Certified to ASME SEC IX and ISO 15610, ensuring international quality and compliance standards.

- Reliable Partner Network: Backed by a network of 27+ vetted suppliers to guarantee consistent quality and timely production.

Got Questions? We’ve Got Answers

Q1. How does VIA INDIGOS ensure the highest quality in fabricated parts?

Answer: Our fabrication processes are certified to ASME SEC IX and ISO 15610 standards, with stringent quality checks at every stage. From material selection to final inspections, we ensure each part meets your specifications.

Q2. Can you handle high-volume production runs while maintaining precision?

Answer: Absolutely! With 27+ advanced facilities and state-of-the-art equipment, we efficiently manage both large-scale industrial volumes and custom requirements without compromising on accuracy or timelines.

Q3. What materials do you work with for fabrication?

Answer: We handle a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, ensuring compatibility with your project needs and industry standards.

Q4. Do you offer support for the entire fabrication process?

Answer: Yes! We provide end-to-end project management, including raw material sourcing, fabrication, surface finishing, and delivery to your door. Our team ensures a seamless process from start to finish.

Q5. How does VIA INDIGOS streamline logistics and delivery?

Answer: We work with a network of 50+ trusted suppliers and leverage advanced supply chain management tools to ensure timely delivery, minimizing downtime and production delays.

Q6. What is the typical lead time for fabricated components?

Answer: Our streamlined processes and vetted supplier network enable us to deliver on tight timelines, even for high-volume orders.

Q7. What surface finishing and testing capabilities do you provide?

Answer: We offer in-house painting, coating, hydrostatic, and pneumatic pressure testing, ensuring your components are both durable and functionally reliable.

Q8. How do you handle specialized fabrication requests?

Answer: We collaborate with you to understand your unique requirements and utilize our global standards-certified welders and advanced facilities to bring your vision to life.

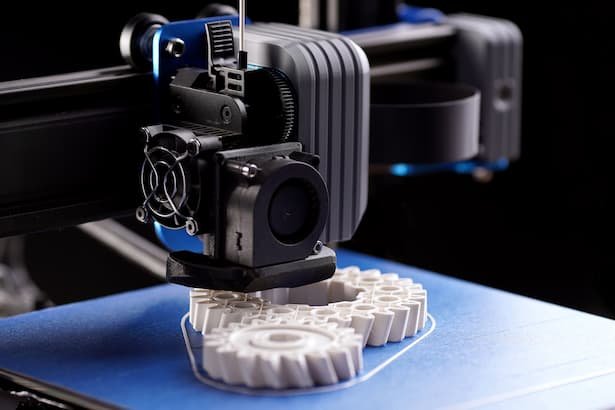

Q9. What measures do you take to maximize tool life and operational efficiency?

Answer: Our VITLM (VIA INDIGOS Tool Life Management) system tracks tool wear, schedules maintenance, and optimizes tool performance, minimizing downtime and ensuring consistent quality. We have a dedicated team to ensure deliver consistency.

Q10. How do you support supply chain efficiency for CNC and VMC projects?

Answer: We leverage our extensive network of manufacturing partners over 1300 HMC & VMC. Our on-ground team to ensure streamlined operations, timely deliveries, and real-time tracking for seamless supply chain management.

Kickstart Your Fabrication Journey Today!

We’ve answered your questions; now let’s showcase how VIA INDIGOS leads in fabrication. From precision welding techniques like

TIG, MIG, and Shielded Metal Arc to advanced processes like rolling, punching, and shearing, our expertise guarantees strength, accuracy, and seamless execution for every project. Let’s take a closer look at the capabilities that bring your designs to life.

Capabilities That Define Excellence

Our Core Techniques

Clean cuts for sheet metal, ideal for large panels or sections.

High-speed processes for repetitive shapes, holes, or embossing.

Cylindrical or curved, critical in structural & industrial fabrication.

For holes with precise diameters and threads.

(Gas Tungsten Arc Welding - GTWA) High-precision welding for intricate components with superior finishes.

Durable and reliable welding for structural and heavy-duty applications.

Efficient, high-speed welding for large-scale projects with complex designs.

Combining components into final structures with consistency.

Materials We Work With

Our expertise spans a diverse range of materials to meet the demands of your project:

Materials Handled:

Titanium | Copper | Monel | Stainless Steel

Nickel Alloys | Copper Alloy | Duplex SS | Inconel

Tantalum & Zirconium | Exotic Metal Cladded | SS Cladded

Not seeing your material here? Don’t worry-reach out, and our team will work with you to find the best solution for your needs!

Finishes

Sand Blasting

Cleans and preps fabricated parts.

Black Oxide

Adds a thin, protective layer.

Galvanizing

Prevents rust on fabricated steel parts.

CED & Powder Coatings

Applies protective coatings.

Anodizing

Provides a protective oxide layer, especially for aluminium parts.

Chrome Plating

Applies a durable corrosion-resistant layer of chromium to enhance surface finish.

Quality Assurance - Conforming to International Standards

BEND IT, WELD IT, SHIP IT—ALL WITH VIA INDIGOS SERVICES!

Our services are designed with your success in mind. Whether it’s maintaining stringent quality checks through VIQAP or ensuring reliable vendor approvals with VIVAP, we’re here to simplify your processes. Your goals become ours, and we strive to deliver value that aligns with your unique needs. With VIA INDIGOS, you’re not just getting services—you’re gaining a partner committed to your growth and efficiency.

Products Manufactured Through Fabrication

Frames

Panels

Structures

Tanks

BEND IT. CUT IT. SHAPE IT - WITH VIA INDIGOS!

Tailored Fabrication for Every Scale – From Small Batches to Large-Volume Manufacturing