What is Contract Manufacturing? A Complete Guide for Beginners

- VIA INDIGOS

Imagine you’re a startup founder with a game-changing product idea. You’ve designed the perfect tech gadget that could revolutionize the market, but now you’re faced with the biggest challenge: How do you produce it at scale without draining your resources? Building a factory seems impossible, hiring and training a production team could take years, and you need to hit the market now before your competitors catch up and steal this idea!

This is exactly where contract manufacturing comes in, the behind-the-scenes Superman that will fuel your growth without the added overwhelm and stress.

Think about Apple: they didn’t build their own factories to produce millions of iPhones. Instead, they partnered with expert manufacturers to bring their designs to life on a massive scale. By outsourcing their production to countries like India, they’ve managed to cut costs, enhance their operations, and dominate markets all over the world.

In this blog, we’ll walk you through the ins and outs of contract manufacturing, like how it works, why it’s a powerful tool for businesses of all sizes, and the exact steps to take to make it work for you. Whether you’re just starting out or looking to scale your operations, this guide will show you how to use contract manufacturing to propel your business to the next level. Let’s dive in.

Welcome to Contract Manufacturing

Contract manufacturing might sound like a complex topic reserved for large-scale corporations. But the truth is, contract manufacturing is not just a money-saving tactic for big brands—it’s an essential growth strategy for businesses of all sizes.

By the end of this guide, you’ll understand why outsourcing your production can lead to massive growth, not only in terms of capacity but also in strategic innovation. More importantly, you’ll see that contract manufacturing isn’t just about reducing costs; it’s about accelerating your ability to deliver value faster and better than ever before.

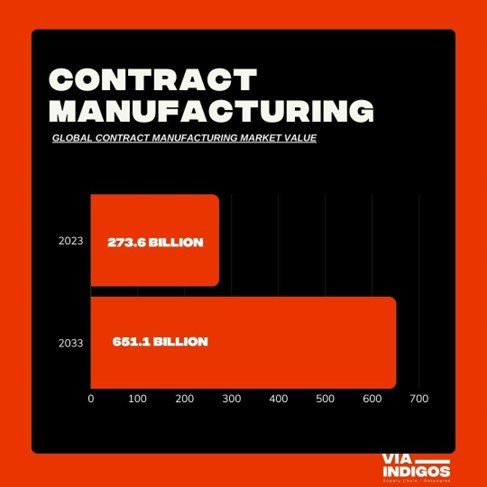

As stated by Market Reasearch Biz#1, “The Global Contract Manufacturing Market was valued at USD 273.6 billion in 2023. It is expected to reach USD 651.1 billion by 2033, with a CAGR of 9.3% during the forecast period from 2024 to 2033”.

The significant expansion of the contract manufacturing market indicates that companies utilizing this approach may experience advantages such as boosted production capacity, cost savings, and scalability, which could contribute to stronger growth outcomes compared to those handling manufacturing internally. Nonetheless, more specific comparative data would require additional focused research.

What is Contract Manufacturing?

At its core, contract manufacturing refers to a business arrangement where a company outsources its production needs to a third-party manufacturer. This means the company focuses on product design, marketing, and sales, while the manufacturing partner handles the actual production of goods.

Contract manufacturers are specialized in creating products on a large scale, ensuring quality control, cost-efficiency, and timely delivery.

The Role of Contract Manufacturing in Global Supply Chains

Contract manufacturing plays a huge role in global supply chains. From electronics to automotive, industries worldwide rely on contract manufacturers to keep their production lines running smoothly. This outsourcing model allows businesses to scale at a faster rate, enter new markets successfully, and compete in an increasingly globalized world.

Imagine launching a new tech gadget in the U.S. while simultaneously entering the European market without the need for new factories or added operational complexities. That’s the power of contract manufacturing.

How Contract Manufacturing Works: A Step-by-Step Process

Let’s break it down step by step. How does a business go from designing a product to having it produced by a contract manufacturer?

Step 1: Identifying the Need for Outsourcing

Every company reaches a point where in-house production becomes either too costly, too slow, or too limiting. When businesses realize that outsourcing production can increase their speed to market or reduce costs without sacrificing quality, they start exploring contract manufacturing.

Key Considerations:

- Are you looking to scale quickly?

- Do you need specialized equipment or expertise that you don’t have in-house?

- Is your production cost getting too high?

Step 2: Researching and Choosing a Contract Manufacturer

Once you’ve identified the need, it’s time to find the right partner. This step is crucial because not all manufacturers are created equal. You need a partner that matches your product needs, budget, and values.

What to Look for:

- Location: Should the manufacturer be local or overseas? Partnering with an overseas manufacturer, particularly in India, can significantly reduce costs and streamline operations. With the right US-India-based partner, you not only save on production expenses but also benefit from a reliable, cross-border approach that eliminates risks and enhances efficiency.

- Certifications: When selecting a contract manufacturing partner, it’s important to make sure they adhere to established industry standards. This means looking for certifications that show their commitment to quality, safety, and operational efficiency. One of the most widely recognized certifications is ISO 9001, which focuses on quality management systems. Manufacturers with this certification have proven that they follow stringent processes to ensure products meet customer and regulatory requirements consistently.

Beyond ISO 9001, depending on the industry, other certifications may be essential. For example:

- ISO 13485 is crucial for medical device manufacturing, ensuring that products meet safety standards.

- ISO/TS 16949 is vital for automotive manufacturers, focusing on quality management specific to this sector.

- ISO 14001 indicates a commitment to environmental management, showing the manufacturer’s efforts to minimize their environmental impact, which is increasingly important for sustainable production.

Certifications like these give you peace of mind that your manufacturing partner not only follows best practices but also continually improves their processes to deliver high-quality results. In addition, working with certified manufacturers can help guarantee regulatory compliance in various global markets, reducing the risk of expensive errors or delays. Always verify the certifications and request proof to make sure your partner is fully compliant.

- Experience: When evaluating a contract manufacturer, their experience in producing products similar to yours is a must. A manufacturer with relevant experience is already familiar with the technical requirements, industry standards, and potential challenges that may come up during production. This experience can greatly reduce the learning curve and speed up the production process, allowing for quicker turnaround times and fewer errors.

![]() Expert Tip

Expert Tip

Always ask for references and speak to companies they’ve worked with. This will give you a real sense of their reliability and capabilities.

Step 3: Setting Up the Agreement

Once you’ve chosen a manufacturer, the next step is to work out the details in a contract. This agreement should cover all aspects of the relationship, including pricing, production timelines, quality control, intellectual property protection, and payment terms.

Common Contract Manufacturing Models:

- OEM (Original Equipment Manufacturer): The manufacturer produces a product based on your design specifications.

- ODM (Original Design Manufacturer): The manufacturer provides design expertise, and you can brand the finished product as your own.

Step 4: Product Design and Prototyping

Before full-scale production begins, a prototype is created to verify that the product meets the company’s standards. This is where any design flaws or issues can be resolved.

Collaboration is Key: During this phase, maintain open communication with the manufacturer to ensure that your vision is being realized. Be ready for multiple iterations until you’re satisfied with the prototype.

![]() Expert Tip

Expert Tip

Document Every Detail – Keep a comprehensive record of every prototype revision, noting feedback, adjustments, and decisions made. This documentation not only ensures clarity between your team and the manufacturer but also streamlines the production process and helps avoid misunderstandings down the line.

From concept to reality; perfecting every detail to bring your vision to life

Step 5: Production and Quality Control

Once the prototype is approved, it’s time for full-scale production. One of the biggest advantages of contract manufacturing is the ability to scale production rapidly without needing to build your own factories or hire additional workers.

But with this scaling comes the challenge of maintaining quality.

How to Guarantee Quality:

- Implement detailed quality control checkpoints throughout the production process.

- Regularly audit the manufacturer to confirm they meet your standards.

- Develop a clear plan for addressing defects or inconsistencies.

Step 6: Managing Supply Chain Logistics

Contract manufacturers often handle more than just production, they can also manage supply chain logistics, including sourcing raw materials and even handling distribution. This can streamline operations and reduce costs, allowing you to focus on sales and marketing.

Benefits of Contract Manufacturing

Now that we’ve covered the process let’s look at the benefits that contract manufacturing can offer your business:

- Faster Time to Market

Contract manufacturers have established production processes and supply chain networks, enabling quicker turnaround times so you can get your product to market faster than if you handled manufacturing in-house.

- Access to Advanced Technology

Contract manufacturers often invest in the latest equipment and technologies, allowing you to leverage cutting-edge production capabilities without the need for costly capital investment.

- Scalable Production

Whether you need small-batch runs or high-volume output, contract manufacturers can adjust production levels to match demand, giving you flexibility and reducing the risk of overproduction or stockouts.

Challenges of Contract Manufacturing (and How to Overcome Them)

1. Quality Control Issues

Quality consistency is a common concern in contract manufacturing, especially with overseas partners who may have different quality standards.

To address this, set up a robust quality control system that includes regular inspections and detailed quality standards. Utilize established procedures like the Production Part Approval Process (PPAP) to verify that each part meets your requirements before full-scale production. Implement Statistical Process Control (SPC) to monitor production variations, and use Failure Modes and Effects Analysis (FMEA) to anticipate potential failures and address them proactively. These methods help ensure consistent quality by identifying and resolving issues early in the process.

Example: If you’re manufacturing a high-precision part for the automotive industry, incorporating SPC can track measurements in real-time to detect deviations before they result in defects. Requiring PPAPs ensures that all parts meet stringent quality standards, while FMEA allows you to analyze potential risks, helping prevent quality slips during large-scale production.

2. Intellectual Property (IP) Risks

IP protection is crucial when working with external manufacturers, as there’s always a risk of your designs or processes being misused or shared. To safeguard your IP, include well-defined IP protection clauses in your contract, specifying ownership and confidentiality terms. It’s also wise to collaborate with manufacturers in countries that uphold strong IP laws, which offer additional legal protection. Regular audits and IP training for the manufacturer can further protect your proprietary information.

Example: A company producing innovative electronic gadgets can protect its unique designs by signing non-disclosure agreements (NDAs) with clear consequences for breaches and stipulating that only authorized personnel access sensitive materials. By choosing a manufacturer based in a country with stringent IP laws, the company has legal recourse if a breach occurs.

3. Communication Barriers

Language and cultural differences can create misunderstandings that lead to production delays or quality issues. To overcome this, establish clear communication channels and designated points of contact who are fluent in the necessary languages and understand cultural nuances. Using project management tools, like Asana or Trello, can help track project milestones, document communication, and ensure alignment. Regular video calls also help build rapport and clarify any miscommunications early on.

Example: A U.S.-based apparel company working with a manufacturer in Vietnam can assign a bilingual project manager to oversee communication, coordinate weekly progress calls, and use a shared project management platform to keep all stakeholders informed and on the same page. This approach minimizes delays and fosters better collaboration across cultural boundaries.

The Future of Contract Manufacturing

Technological Innovations

Emerging technologies like automation, artificial intelligence (AI), and robotics are reshaping contract manufacturing by enhancing speed, precision, and adaptability. Automated processes reduce human error and increase production speeds, allowing manufacturers to meet high-volume demands without sacrificing quality. AI can analyze large amounts of data to predict maintenance needs, optimize workflows, and manage inventory in real-time, making operations smoother and more financially sound. Robotics add flexibility to the assembly line, quickly adjusting for different product designs without costly reconfigurations.

Sustainability in Manufacturing

As demand grows for environmentally responsible products, contract manufacturers are integrating green practices into their operations. These include using renewable energy sources, reducing waste through efficient resource management, and incorporating recycled or eco-friendly materials. Many contract manufacturers are also adopting circular economy principles, where products are designed for easy disassembly and recycling, creating less waste and allowing for component reuse.

![]() Expert Tip

Expert Tip

Assess Your Manufacturer’s Tech Capabilities and Sustainability Practices Early – Before signing with a contract manufacturer, evaluate their commitment to technology and sustainability. Request a tour (virtual or in-person) to see their automation, AI, or robotics in action, and ask for documentation on their sustainability initiatives.

Real-Life Success Story

Let’s take a look at a few success stories to see how businesses are leveraging contract manufacturing to scale rapidly.

Case Study: Apple Moves to India for its iPhone 16 Production

Apple made the decision to diversify its reliance on China and manufacture the new iPhone in India. As stated in Observer: “Apple’s iPhone manufacturing in India is ramping up quickly. In its last fiscal year ended in September, Apple doubled its iPhone production in India to $14 billion worth from the previous year, Bloomberg reported in April. Today, 1 in 7 iPhones sold globally are made in India. Apple aims to make a quarter of all iPhones in India in the next four years.”

This decision has not only benefited the Indian job economy, but it has also positioned Apple to reduce costs, scale production, and increase resilience in its supply chain while tapping into a growing consumer market in the region.

Apple case study

How to Get Started with Contract Manufacturing

If you’re considering contract manufacturing for your business, here’s a quick checklist to help you assess whether it’s the right fit:

- Do you need to scale production quickly?

- Are you struggling with high production costs?

- Do you lack the specialized equipment or expertise needed to produce your product in-house?

Once you’ve answered these questions, start researching potential contract manufacturers, focusing on their location, certifications, experience, and track record.

Conclusion: The Strategic Move of Contract Manufacturing

Outsourcing your manufacturing to a trusted partner can unlock tremendous growth opportunities for your business. It allows you to focus on what you do best, innovating, selling, and building your brand, while your contract manufacturer handles the production process.

If you’re ready to explore contract manufacturing as a strategic tool for growth, now’s the time to take action.

Ready to Scale with Contract Manufacturing? Let’s Talk.

At VIA INDIGOS, we specialize in helping businesses streamline their production and scale with confidence. Contact us today for a free consultation, and let’s discuss how we can help you grow.