Small Business Supply Chain Hacks: How to Stay Ahead

- VIA INDIGOS

Running a small business in today’s world isn’t just about having a great product or service, it’s about making sure that product gets where it needs to be, when it needs to be there.

For small businesses, supply chain disruptions can be costly and frustrating. But with the right strategies, you can take control and stay ahead.

Supply chain disruptions can cripple businesses of any size, but for smaller operations, they can be even more damaging.

The good news? With the right strategies, you can take control, cut costs, reduce delays, and scale efficiently.

Here’s how you can optimize your supply chain, reduce delays, and keep your business running smoothly.

Master Root Cause Analysis – Get Hands-On with Your Supply Chain

Process Analysis: Small or Big; issues don’t come out of nowhere—there’s always a root cause.

Most supply chain problems don’t appear out of nowhere. There’s always a root cause, whether it’s a supplier delay, a miscommunication, or an inefficient process.

The best way to identify these issues? Get hands-on.

• Visit production sites and suppliers regularly to understand their operations, identify potential slowdowns, and assess their reliability.

This direct interaction provides valuable insights into how efficiently your suppliers operate and whether they meet your standards for quality and speed.

• Ask detailed questions about potential bottlenecks – are there staffing shortages, outdated equipment, or logistical inefficiencies?

Identifying specific pain points helps businesses anticipate future issues and implement contingency plans before problems escalate.

• Analyze past delays and patterns by reviewing historical data on shipping times, order fulfillment, and supplier performance.

This helps businesses pinpoint recurring weaknesses and implement corrective actions to prevent similar delays in the future.

Pro Tip: Never rely solely on what your supplier tells you. Cross-check their claims with actual production floor visits or real-time production data to verify efficiency.

Being proactive rather than reactive allows you to address small problems before they become major disruptions.

Gain Visibility into Your Production and Suppliers

Many small businesses operate on blind trust when it comes to their suppliers. But visibility is everything.

If you don’t know what’s happening at the production level, you can’t anticipate or prevent problems.

• Use digital tracking tools and supply chain software to monitor orders, inventory levels, and production schedules in real time.

Implementing IoT-enabled tracking devices or cloud-based ERP (Enterprise Resource Planning) solutions can significantly improve transparency and responsiveness.

• Maintain open communication with suppliers through structured reporting systems – weekly or bi-weekly progress reports help track production timelines and prevent last-minute surprises.

Establishing strong supplier relationships encourages accountability and quicker problem resolution.

• Work with multiple backup suppliers and regional vendors so you’re not entirely dependent on one source.

If an international supplier experiences disruptions, having a local or regional backup can keep your operations running without severe delays.

Pro Tip: Always have a “Plan B” supplier onboarded and pre-vetted. Many businesses wait until they need one, which is already too late.

Having visibility gives you the ability to pivot quickly when challenges arise and make data-driven decisions.

Supplier Performance Management & Continuous Improvement

• Regular Supplier Audits: Conduct quarterly or annual supplier audits to ensure compliance with your standards for quality, lead times, and operational efficiency.

• Developing Long-Term Supplier Relationships: Instead of constantly switching vendors for minor cost savings, building strong relationships with reliable suppliers leads to better pricing, priority fulfillment, and long-term benefits.

• Establishing KPIs for Suppliers: Track supplier performance metrics like on-time delivery rates, defect rates, responsiveness, and lead time trends to ensure they align with your business needs.

• Early Supplier Involvement (ESI): Engage suppliers early in product development to ensure cost-efficient designs, material availability, and optimized manufacturing processes.

Pro Tip: Don’t just track supplier performance—incentivize it. Implement a tiered reward system where top-performing suppliers get better payment terms, priority orders, or long-term contracts. This ensures mutual commitment to continuous improvement.

Supplier Management: Strong Contracts, Audit, track, and build for long-term success.

Improve Communication to Avoid Costly Delays

Many supply chain disruptions happen due to poor communication. When expectations, specifications, or deadlines aren’t clear, mistakes happen.

• Ensure all order specifications and quality requirements are explicitly documented to avoid confusion between your business and suppliers.

Using detailed agreements, drawings, and compliance checklists ensures that all parties understand product expectations.

• Use project management tools like Trello, Monday.com, or Asana to create a centralized communication hub.

These platforms help suppliers, logistics teams, and internal staff stay aligned on deadlines, production status, and potential delays.

• Follow up religiously and request progress updates at key milestones. Never assume things are on track without confirmation.

Regular video calls, check-ins, and real-time reporting help prevent miscommunications that could lead to costly errors.

Pro Tip: Don’t rely solely on emails. A quick video call can resolve potential misunderstandings way faster than long email threads.

Seems like a normal thing but people often fail to meet this simple technique.

Partnering with the right team ensures streamlined production from start to finish.

Build Agility into Your Supply Chain

A rigid supply chain is a fragile one. If you don’t have contingency plans, one unexpected delay can throw your entire business off track.

• Diversify your supplier base across different regions so that disruptions in one location don’t shut you down.

By sourcing from multiple suppliers in different geographic areas, businesses can mitigate risks related to weather events, political instability, or economic shifts.

• Consider nearshoring and reshoring strategies – sourcing suppliers closer to home can reduce lead times, lower shipping costs, and provide more control over production quality.

This is particularly beneficial for businesses that rely on just-in-time inventory models.

• Stock critical inventory strategically by analyzing demand patterns and seasonal fluctuations.

Rather than overstocking everything, focus on maintaining buffer stock for high-demand or high-risk components to ensure smooth operations during peak periods.

Pro Tip: Test your contingency plans with real data, not assumptions.

Simulate a supplier shutdown, customs delay, or demand spike and see if your current setup holds.

Run a limited batch order with your backup supplier to check if they can meet your quality and lead time standards before you need them.

Freight & Customs Optimization for International Sourcing

• Understanding Freight Terms (FOB, CIF, EXW, etc.): Structuring contracts correctly can avoid unnecessary shipping costs and improve cash flow.

• Optimizing Customs & Duties: Take advantage of Free Trade Agreements (FTAs) and strategic warehousing to cut down import/export costs.

• Leveraging Consolidated Shipments: When to consolidate smaller shipments vs. when to use direct shipping to balance cost and lead time.

Pro Tip: AI tools are great, but nothing beats your own industry experience. Always cross-check AI insights with ground realities.

Supply Chain AI- Track Material, nearshore smartly, and stock strategically to keep your supply chain disruption-proof

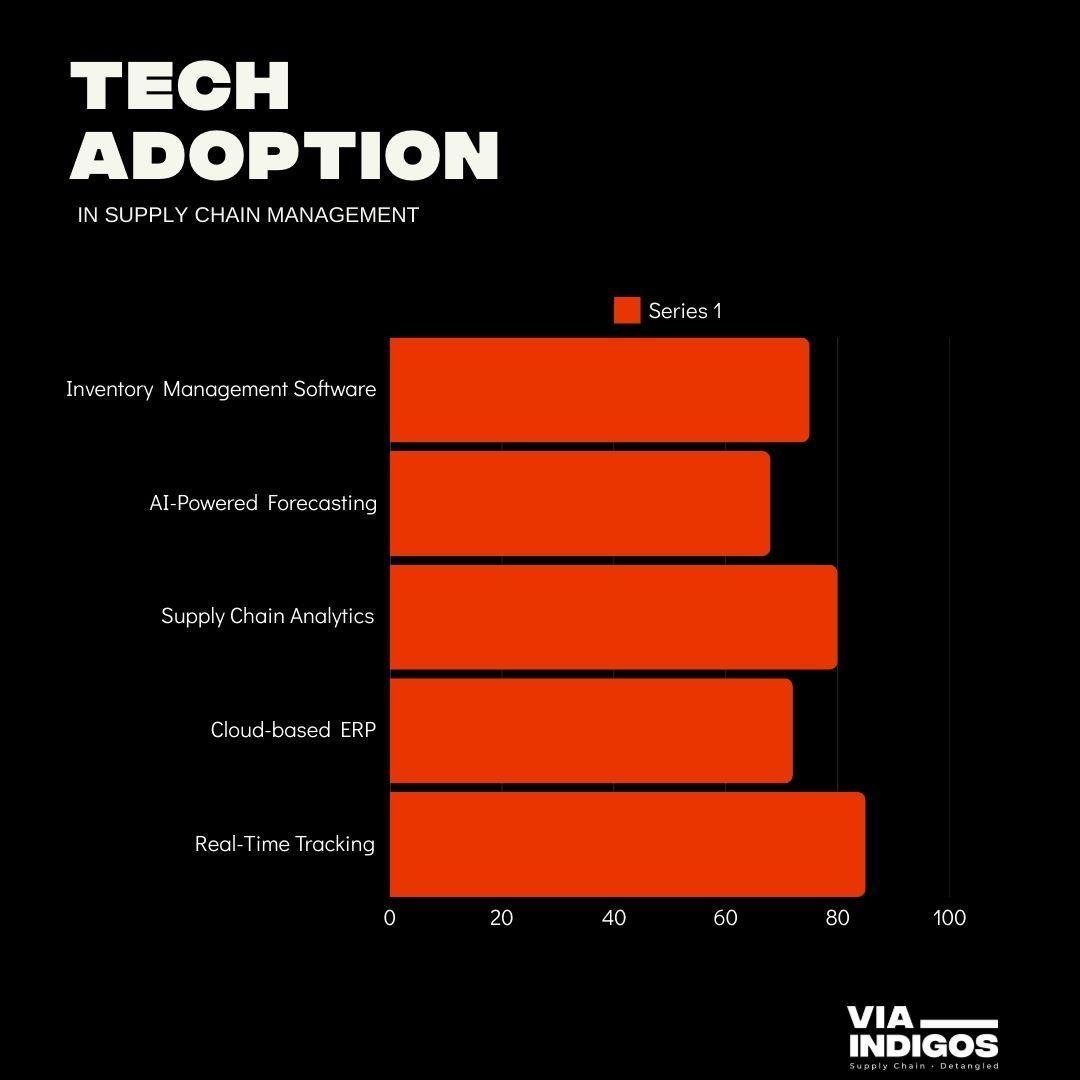

Leverage Technology for Smarter Supply Chain Management

Gone are the days when small businesses had to manage supply chains with spreadsheets and phone calls.

Affordable digital tools now make it easier than ever to stay organized and efficient.

• Invest in advanced inventory management software such as NetSuite, Zoho Inventory, or TradeGecko to automate stock monitoring, generate low-stock alerts, and streamline reordering processes.

• Utilize supply chain analytics tools to predict demand trends and optimize logistics – AI-driven solutions can analyze past sales, seasonal fluctuations, and external factors like market trends to help businesses adjust their procurement and inventory strategies accordingly.

• Implement AI-powered forecasting and predictive modeling to reduce waste and improve supply chain responsiveness.

Predictive analytics tools help businesses identify optimal ordering times and reduce excess stock that can tie up capital.

Pro Tip: Don’t just integrate technology—align it with your decision-making. Use machine learning models to simulate different demand scenarios, and link them with automated purchasing triggers to dynamically adjust orders before shortages or overstock happen.

Inventory Optimization Hacks

• ABC Analysis: Prioritize inventory based on value and sales frequency, ensuring that high-priority items receive the most attention.

• Safety Stock Calculations: Maintain buffer stock for critical components without overstocking unnecessary items.

• Reorder Point Optimization: Use data-driven forecasting to determine the optimal point to replenish inventory before stockouts occur.

• Vendor-Managed Inventory (VMI): Work closely with suppliers to streamline replenishment and reduce carrying costs.

Pro Tip: Don’t treat ABC analysis as static. Reclassify inventory every quarter based on shifting demand patterns.

A product that was C-category last season could become A due to market trends, and vice versa.

Dynamic categorization ensures optimal stock levels without guesswork.

Inventory Optimization- Optimize stock levels with ABC analysis, safety stock, and data-driven reorder points.

Risk Mitigation & Contingency Planning

• Supplier Failure Preparedness: Have backup suppliers vetted and ready to step in when needed.

• Political & Economic Risk Assessment: Monitor geopolitical risks and trade policies that may impact global sourcing.

• Demand Surge Readiness: Implement dynamic supply chain strategies that can scale production up or down based on real-time demand.

• Disaster Recovery Plans: Ensure alternative logistics routes, emergency stockpiles, and responsive contingency plans are in place to handle supply chain shocks.

Pro Tip: Vet your backup suppliers as rigorously as your primary ones—before you need them.

Have a pre-negotiated contract in place so you’re not scrambling during a crisis.

Also, geographically diversify critical suppliers to avoid single-region dependency.

Don’t ever be clueless; Vet backup suppliers, monitor risks, and plan ahead to stay resilient.

Sustainable & Ethical Sourcing for Competitive Advantage

• Ethical Supplier Vetting: Avoid compliance issues by working only with suppliers that follow fair labor practices, environmental regulations, and industry standards (e.g., ISO, RoHS, UL, REACH compliance).

• Cost Savings from Sustainability Initiatives: Eco-friendly packaging, lean manufacturing, and optimized transportation routes don’t just benefit the environment—they reduce waste and cut costs in the long run.

• Government Incentives for Sustainable Practices: Many countries offer tax breaks, grants, and subsidies for businesses adopting green manufacturing and sustainable sourcing practices.

Pro Tip: Sustainability isn’t just a compliance check—it’s a cost-cutting tool.

Conduct a waste audit with suppliers to reduce material usage, optimize packaging, and identify reusable components.

Many businesses save 5-10% on material costs with these audits alone.

Supply Chain Sustainability: Cut costs, reduce waste, and gain a competitive edge with ethical sourcing.

How VIA INDIGOS Can Help

At VIA INDIGOS, we help businesses—both small and mid-sized—strengthen their supply chains by providing hands-on expertise, real-time visibility, and strategic planning.

From supplier performance management to risk mitigation and sustainable sourcing, we tackle the complexities so you can focus on growth.

Whether you’re optimizing inventory, integrating technology, or future-proofing your supply chain, our tailored solutions enhance efficiency, reduce risks, and drive profitability.

Don’t let supply chain disruptions slow you down. Visit www.viaindigos.com to learn how we can help you build a resilient, efficient, and agile supply chain.

Partnering with the right team ensures streamlined production from start to finish.

Final Thoughts

Small businesses that actively manage their supply chains gain a major competitive edge.

By staying hands-on, improving visibility, strengthening communication, and embracing technology, you can avoid costly disruptions and keep your business running smoothly.

Supply chain challenges are inevitable, but how you handle them makes all the difference.

Take control, stay ahead, and watch your business thrive.

3 comments