Supply Chain Superstars: The Unsung Heroes of Business

- VIA INDIGOS

When we think about the products we use every day, our smartphones, clothes, groceries, and even medical supplies, it’s easy to overlook the complex web of professionals who make it all possible. Behind every package delivered and product manufactured is a network of workers whose dedication and expertise keep the supply chain moving. These supply chain superstars ensure the world runs smoothly, often without recognition. Let’s shine a spotlight on these unsung heroes and explore the vital roles they play in business success.

1. Designing Engineers: The Blueprint Creators

Every product begins as an idea, but it’s the designing engineers who transform that idea into a tangible reality. They create detailed blueprints that manufacturers follow to produce goods.

• What They Do: Designing engineers don’t just sketch ideas; they solve puzzles. They consider how materials, production methods, and end-user needs fit together seamlessly. Imagine crafting a smartphone case that’s sleek but tough enough to survive a drop, that’s their challenge.

• Challenges: Balancing innovation with practicality is no small feat. With consumers increasingly demanding sustainable products, designing engineers are constantly asking, “How can we make this greener without sacrificing quality?”

Reverse Engineering: Turning Blueprints into Reality with Precision and Innovation.

2. Quality Engineers: Guardians of Standards

Quality engineers are the gatekeepers of excellence, ensuring that every product meets rigorous standards before reaching consumers.

• What They Do: Think of quality engineers as detectives. They hunt for potential flaws, a weak weld, an uneven seam, or a tiny misalignment, and eliminate them before they become big problems. Their goal? Ensure every product is as good as the first.

• Challenges: Speed is the enemy of quality. In industries like automotive, a single defective part can cause recalls affecting thousands of vehicles. Quality engineers must maintain precision even under tight deadlines.

Quality Engineers: Ensuring Flawless Products with Rigorous Standards and Precision under Pressure.

3. Production Engineers: Efficiency Experts

Production engineers ensure that manufacturing processes are optimized for speed, cost-effectiveness, and safety.

• What They Do: Picture a factory floor buzzing with activity. Machines are humming, conveyor belts are moving, and workers are assembling parts. Production engineers ensure this organized chaos stays efficient and safe.

• Impact: By tweaking workflows or upgrading machinery, production engineers can shave minutes off production time, a small change that can save companies millions annually.

Quality Production Engineers: Optimizing Manufacturing Efficiency, Reducing Costs, and Enhancing Factory Safety.

4. Freight Forwarders: The International Coordinators

Freight forwarders play a pivotal role in managing the movement of goods across international borders. They’re the backbone of global trade.

• What They Do: Freight forwarders are like travel agents for products. They plan routes, book carriers, and handle customs paperwork to ensure goods arrive on time. It’s their job to juggle multiple shipments and keep everything running smoothly.

• Challenges: With fluctuating fuel prices and trade wars, they’re constantly adapting. It’s not uncommon for freight forwarders to re-route shipments mid-journey due to unexpected port closures or political tensions.

Freight Forwarders: Ensuring Seamless Global Trade with Expert Logistics, Customs Handling, and On-Time Delivery

5. Clearing Agents: Navigators of Bureaucracy

Clearing agents handle the intricate web of customs regulations, ensuring goods pass smoothly through borders.

• What They Do: Clearing agents are the unsung heroes of international trade. They decipher dense customs documents, calculate tariffs, and resolve disputes with border officials. Their expertise prevents costly delays.

• Impact: Efficient clearing agents can mean the difference between a product hitting store shelves on time or missing its season entirely.

• Challenges: Policies change often, and staying updated is a full-time job. They also face pressure to expedite shipments without compromising compliance.

Clearing Agents: Simplifying Customs, Navigating Tariffs, and Ensuring Hassle-Free Cross-Border Trade.

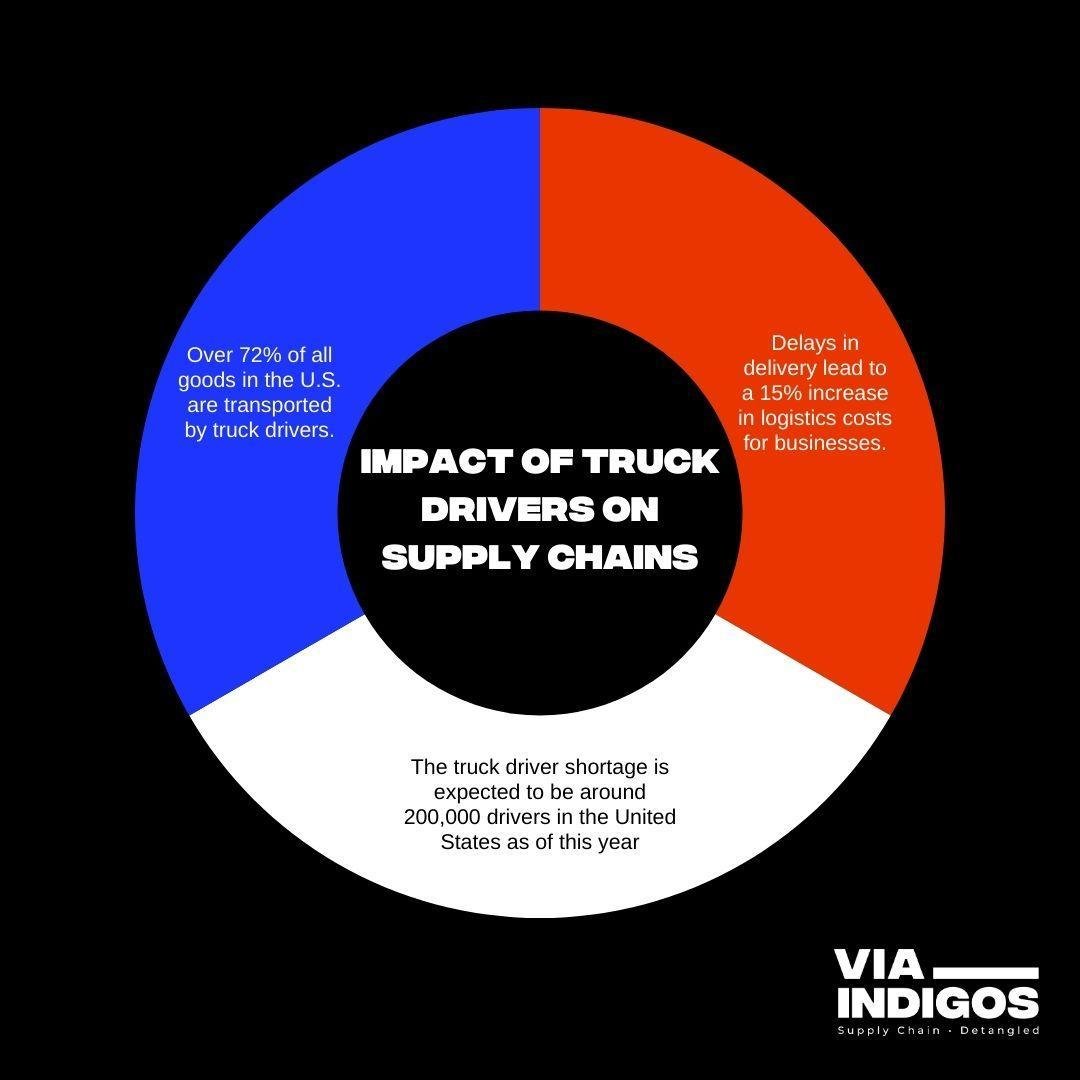

6. Truck Drivers: The Final Mile Champions

Truck drivers are the unsung heroes of logistics, bridging the gap between warehouses and consumers. They handle the final and often most challenging leg of the supply chain.

• What They Do: Think of truck drivers as the glue holding the supply chain together. They navigate traffic, bad weather, and tight schedules to get goods where they need to go. Every package on your doorstep owes its journey to a driver.

• Challenges: The rise of e-commerce has pushed drivers to the limit. Tight delivery windows, long hours, and driver shortages make this a tough but indispensable job.

• The Reality: Truck driver shortages have led to a 20% increase in average delivery times over the last five years, underscoring their vital role in the supply chain, emphasizing the importance of truck drivers in cost optimization.

Truck Drivers: Powering the Final Mile of Logistics, Ensuring Timely Deliveries and Supply Chain Efficiency.

7. Warehouse Workers: Masters of Inventory

Warehouse workers ensure that goods are stored, sorted, and shipped efficiently, acting as the central hub of the supply chain.

• What They Do: Imagine a giant puzzle where pieces constantly move. Warehouse workers manage this dynamic puzzle, ensuring the right products are picked, packed, and shipped without delay.

• How this Helps: Warehouses equipped with automation see a 30-40% increase in productivity, but human workers remain essential for tasks requiring judgment and flexibility.

• Challenges: Peak seasons like holidays can turn warehouses into pressure cookers, with workloads doubling almost overnight.

Warehouse Workers: Streamlining Inventory Management, Packing Precision, and Efficient Order Fulfillment.

8. Logistics Managers: The Orchestrators

At the heart of every supply chain is the logistics manager, who coordinates the movement of goods from start to finish.

• What They Do: Logistics managers are master planners. They ensure the right product gets to the right place at the right time, all while keeping costs down. Think of them as the conductors of a massive symphony.

• Impact: When done right, logistics management ensures shelves are stocked and customers are happy. When done wrong, it can mean empty stores and unhappy customers.

• Challenges: They’re constantly putting out fires, whether it’s a delayed shipment, a broken-down truck, or a port strike.

With boots on the ground and a vast network of production partners in INDIA, we help you cut tariffs, reduce lead times and avoid supply chain disruptions.

9. Supply Chain Analysts: Data-Driven Problem Solvers

Behind the scenes, supply chain analysts use data to identify inefficiencies and optimize processes.

• What They Do: Analysts crunch numbers to predict demand, identify bottlenecks, and streamline operations. They turn raw data into actionable insights that keep supply chains running smoothly.

• Where it Counts: Companies that use advanced analytics in supply chain management report a 30% improvement in efficiency.

• Challenges: Supply chain complexity is growing, and analysts must process more data than ever to stay ahead.

Supply Chain Analysts: Driving Efficiency with Data Insights, Predictive Analytics, and Process Optimization.

The Human Impact of Supply Chain Gaps

When any link in the chain falters, the effects ripple across industries. For instance:

- • A shortage of truck drivers can delay deliveries, leading to stockouts in stores.

- • Inefficient customs clearance can result in missed deadlines, tarnishing brand reputations.

- • Gaps in warehouse staffing during peak seasons, like holidays, can disrupt fulfillment schedules.

Conclusion: Celebrating the Superstars

The supply chain isn’t just a system of processes—it’s powered by people. From the designing engineers sketching blueprints to the truck drivers delivering packages, every role is vital. These supply chain superstars work tirelessly behind the scenes, ensuring businesses succeed and consumers are satisfied.

Next time you receive a package or pick up a product from a store, take a moment to appreciate the network of professionals who made it possible. They truly are the unsung heroes of business, deserving of recognition and gratitude for their contributions to our daily lives.

Why VIA INDIGOS for Supply Chain Excellence?

At VIA INDIGOS, we believe that a resilient supply chain is the backbone of any successful business. From sourcing the right materials to managing logistics and ensuring on-time delivery, we take the complexity out of supply chain management so you can focus on growing your business.

Our expertise spans across industries and processes, backed by a robust network of manufacturing partners and a deep understanding of global markets. With our strategic approach, we help businesses navigate supply chain challenges, reduce costs, and achieve operational efficiency.

What Sets VIA INDIGOS Apart?

• Unmatched Expertise: Years of experience in managing diverse supply chains, ensuring seamless operations across multiple industries.

• Cost Optimization: Leverage India’s manufacturing advantages to reduce tariffs, control costs, and stay competitive.

• Global Standards: All our production partners are certified and meet the highest quality standards, including ISO 9001, IATF 16949 and much more.

• Comprehensive Solutions: From procurement to packaging and logistics, we handle every aspect of your supply chain.

• Reliable Partner: With on-ground teams in India, we ensure transparency, precision, and timely delivery at every step.

At VIA INDIGOS, we don’t just manage your supply chain—we transform it into a strategic advantage, making your business more agile, cost-efficient, and future-ready.